NO.1 surface treated by heat treatment and pickling after hot rolling. The appearance is silver white, matt and bright. This surface is suitable for industries that require heat resistance and corrosion resistance, and the surface brightness is not important. Common applications include industrial tank and chemical industrial plants etc..

2D surface treated by heat treatment and pickling after cold rolling. The appearance is silver white, smoother but of matt grain. Common applications include petrochemical production equipment, automotive components, building materials and water pipes etc..

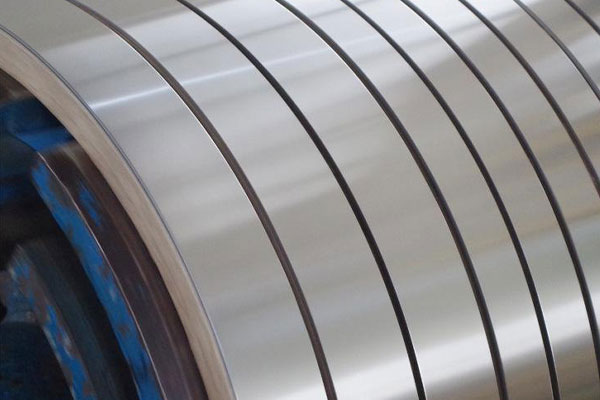

After 2D treatment, the final process is lightly cold rolled by a polishing roller to obtain proper gloss. The appearance is smooth and bright, and easy to re-grind to make the surface more brighter. Common applications include building materials, tableware etc..

NO.4 is a product ground with a grinding belt of size 150-180. It has better gloss, discontinuous rough lines and finer stripes than No.3 stainless steel castings commonly used polished and sanded surfaces. Common applications include food processing equipment, home electrical products, medical equipment etc..

BA surface is also produced by cold rolling and de-scaling. It has excellent surface gloss, high reflectivity. In addition, The very smooth surface also makes this surface highly suitable for further finishing processes such as mirror polishing and chrome plating. Common applications include catering equipment etc..

HL use a polishing abrasive belt with an appropriate particle size (150-320 mesh) to grind, with obvious straight stripes. The surface is beautiful, good texture and scratch is not obvious, durable, wear-resistant. Common applications include building decoratio, elevators, vehicle parts, etc..

Mirror is produced by polishing with successively finer abrasives and buffing extensively until all grit lines from preliminary grinding operations are removed. The feature is highest reflectivity. Mainly used for interior and exterior decoration materials of automobiles and buildings.

English

English Русский

Русский