E-mail : service@ronsteel.comPhone : +8617773160488

- Home

- About Us

- Product & Service

- Stainless Steel Plate

- 304/304L/304H STAINLESS STEEL PLATE

- 316/316L STAINLESS STEEL PLATE

- 321/321H STAINLESS STEEL PLATE

- 310/310S STAINLESS STEEL PLATE

- 309/309S STAINLESS STEEL PLATE

- 2205/2507 STAINLESS STEEL PLATE

- 904L STAINLESS STEEL PLATE

- 410/410S STAINLESS STEEL PLATE

- 420/430 STAINLESS STEEL PLATE

- 304 Stainless Steel Chequered Plates

- Stainless Steel Coil

- 304/304L/304H STAINLESS STEEL COIL

- 316/316L STAINLESS STEEL COIL

- 321/321H STAINLESS STEEL COIL

- 310/310S STAINLESS STEEL COIL

- 309/309S STAINLESS STEEL COIL

- 2205/2507 STAINLESS STEEL COIL

- 904L STAINLESS STEEL COIL

- 410/410S STAINLESS STEEL COIL

- 420/430 STAINLESS STEEL COIL

- 304 Stainless Steel Chequered Coils

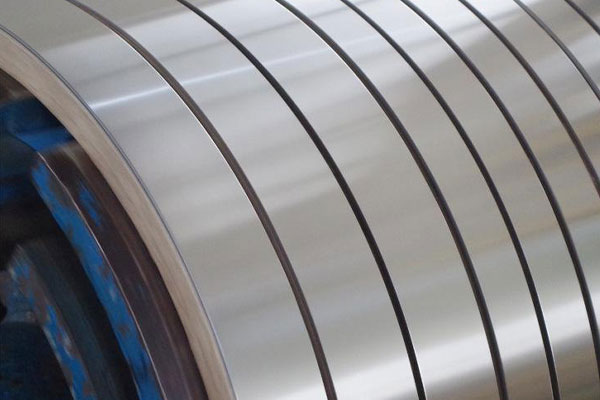

- Stainless Steel Strip

- Nickel Alloy Plate

- Nickel Alloy Coil

- Nickel Alloy Strip

- Processing Service

- Stainless Steel Plate

- Quality Assurance

- Project

- News

- Contact

Request A Quote

English

English Русский

Русский