-

Different international standards for stainless steel

Globally, different countries and regions have established their own stainless steel standards, primarily including ASTM/ASME in the United States, EN (DIN) in Europe, JIS in Japan, and GB in China. These standards differ significantly in terms of chemical composition, mechanical properties, corrosion resistance, and application areas.

More Details

-

Mixed Use of Stainless Steel and Nickel Alloys in Engineering Projects

In modern industry and engineering, stainless steel and nickel alloys are widely used due to their excellent corrosion resistance, high-temperature strength, and mechanical properties. However, in some complex working conditions, a single material may not meet all requirements, so a mixed use of stainless steel and nickel alloys has become a common solution.

More Details

-

Stainless Steel Use in Different Projects

Stainless steel plays a key role in numerous industrial and civil engineering projects due to its excellent corrosion resistance, high strength, and long service life. However, the demand for stainless steel, specification requirements, and application scenarios vary significantly across different industries.

More Details

-

The Use Proportion of Different Stainless Steel Grades in Chemical Facilities

In the chemical industry, the material selection for production lines and equipment directly impacts production efficiency, safety, and service life. Stainless steel, due to its excellent corrosion resistance, high strength, and good processability, is the preferred material for chemical equipment manufacturing.

More Details

-

Stainless Steel in Oil&Gas Industry

High temperature sulfur and cyclohexane acid corrosion; the top condensation area needs to be resistant to wet HCl corrosion, and 321 is commonly used

More Details

-

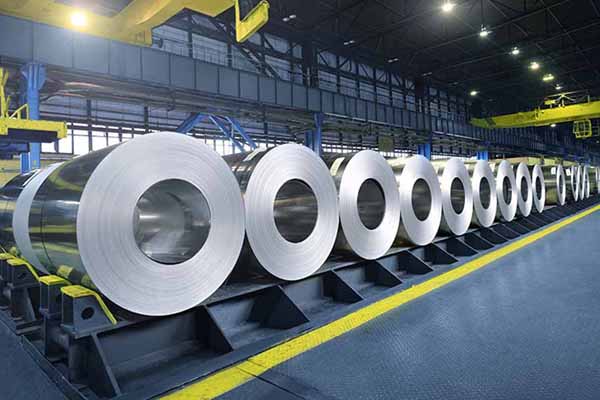

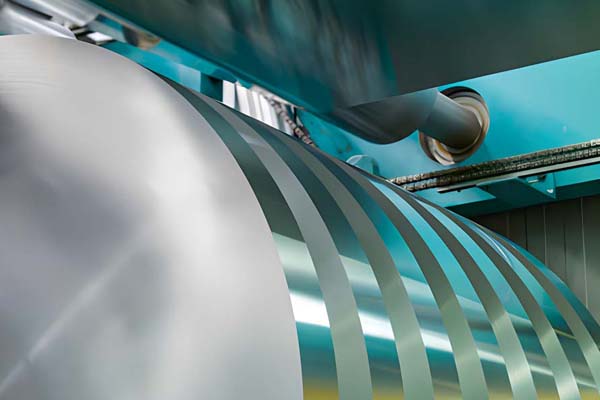

Stainless Steel Plate Thickness and Industry Applications

Stainless steel plates can be categorized by thickness into medium-thick, thick, and extra-thick plates.

Thin plates are generally 4mm thick or less and are widely used in building interior decoration.

Thick plates include 4-25mm and 25-100mm.

More Details

English

English Русский

Русский