With the rapidly development of the global stainless steel industry, it has been widely used around the world. Some media in the air that are corrosive to stainless steel, such as chlorine, sulfur, etc. After the pickling passivation process, a chromium oxide film will form on the surface of the stainless steel, which can prevent intergranular corrosion of stainless steel by harmful ions. After the pickling passivation process, a chromium oxide film will form on the surface of the stainless steel, which can prevent intergranular corrosion of stainless steel by harmful ions. Due to the surface of stainless steel is covered with a very thin and dense passivation film, it solates the corrosive medium, and is the basic barrier of stainless steel protection. Therefore, the passivation process is indispensable for the corrosion resistance of stainless steel plate sheet.

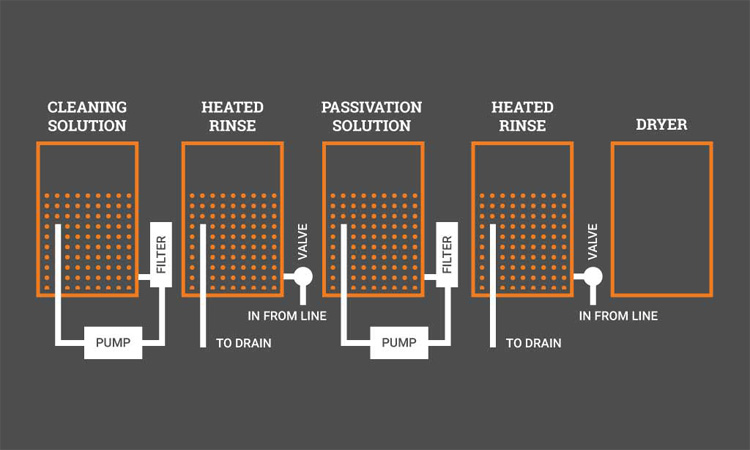

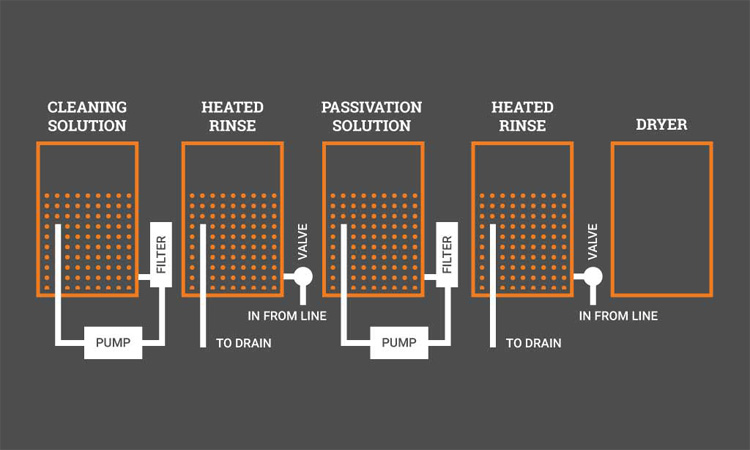

Passivation Process:

First, Removing grease, in order to ensure that the outer layer of the part is free of any stains.

Second, Activation,the rust welding on the outer layer of the part needs to be removed. It can be activated by pickling.

Third, Passivation, soaking the parts in a tank, filling with stainless steel passivation solution for half an hour.If the demand of salt spray is high, it will soak for more than 30 minutes.

Fourth, Neutralize, it needs to be soaked for three minutes, and it is necessary to ensure that the shape of the outer layer is simple, and there are no threads or blind holes.

Fifth, Washing with pure water, making sure there is no residual dirt on the outside of the part.

The principle of passivation process:

The passivation process is to use the method of immersion to make the outer layer of stainless steel produce a chemical reaction, forming a rigorous film. It can improve the rust and corrosion resistance of the stainless steel outer layer.

The advantages of passivation are as follows:

First, The purpose of passivation is to improve the corrosion resistance and oxidation resistance of stainless steel workpieces. After being treated with stainless steel passivation solution, which can improve the stainless steel workpiece have excellent corrosion resistance, anti-rust ability can be improved at least 5-20 times,improvetest time of salt spray resistance, extend the life of the workpiece.

Second, Passivation does not change any size and color of the workpiece, protect the beautiful appearance and precision of the workpiece effectively. It has low cost and liquid can be reused. Realizing material rust-proof grade from secondary to strong.

Third, It is easy to operate, just need to soak.Having safe and friendly operating enviroment. It does not change the material composition and does not affect the electrical conductivity of the material.

English

English Русский

Русский