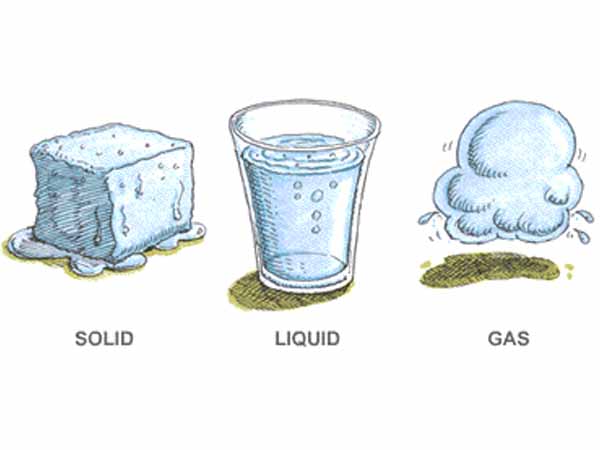

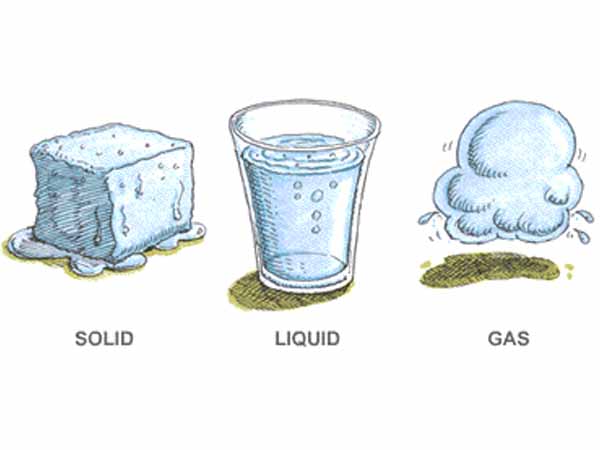

Heat changes the chemical or physical structure of just about everything. Most solids reach a certain temperature, they change their state. Such as ice, warm ice up enough, when it reaches a temperature, it will melt back to its liquid form, this temperature known as the melting point. Continue to heat the liquid, and it will eventually become a gas. Metal is similar to water.

When metals exposed to a high enough temperature, the melting point, it will melt. When subjected to high heat that doesn’t reach the melting point, it also will soften. Beacause soft metals are more malleable, artisans or metal workers can bend them into beautiful or useful shapes. All metal does not have the same melting point. Not even all grades of the same metal will melt at the same temperature. Let’s talk specifically about stainless steel’s melting point.

Stainless steel’s melting point falls between 2550 and 2790°F or 1400 and 1530°C. Why a range? Why not just a single point on the thermometer? BeacauseThe melting point of a particular type of stainless steel depends upon its exact chemical composition. The major elements composing stainless steel are iron, chromium, and nickel, stainless steel comes in five families and more than 150 grades, each grade of stainless steel has a slightly different mix of elements. Consequently, the exact melting point varies across different grades. The two most popular grades are 304 stainless steel and 316 stainless steel, blongs toaustenitic stainless steelfamily, which includes about two-thirds of the stainless steel produced. Austenitic stainless steel features a face-centered cubictructure, which remains constant across all temperatures from cryogenic to the melting point.

How to determine the melting point of stainless steel? Researchers ascertain the melting point of an element or alloy by the capillary method. They pack a sample of the material into a thin-walled capillary melting point tube located next to a heat source and a precise thermometer, then increase the temperature at a rate of one degree Celsius each minute. When the material inside the tube reaches a completely liquid state, the researchers record the temperature as the material’s melting point.

The melting point matters to the workers. If you are a metal worker or engineer who processes stainless steel in a high temperature setting, you need to know the melting point. Otherwise, you might turn a once useful piece of steel into a mess. For users, the melting point is also an important.

High temperatures affect most metals’tensile strength. Tensile strength matters to the user. For stainless steel, when exposed to extreme heat, steel becomes more rigid and easier to bend, this usually happens at about 1000°C. If you are making a steel basket that will hold heavy objects in an extremely hot environment, the tensile strength of that basket will determine how much weight it can bear. Besides, the melting point can helps determine an object’s resistance to oxidation and sulfurization. Consequently, for users, the melting point is also an important parameter to consider when choosing materials or fabrication techniques for stainless steel.

English

English Русский

Русский