Do You Know Cutting Processes of Stainless Steel?

Date:2023-03-22View:989Tags:Ronsco, Stainless Steel Plate, Stainless Steel Cutting

Cutting technology is often used in processing stainless steel, and there are many types of cutting technology. They are divided into stainless steel laser cutting, water cutting, plasma cutting and wire cutting. These four cutting types are described in detail below:

Laser cutting: Laser cutting is the use of focused high-power density laser beam to irradiate stainless steel materials, make the irradiated stainless steel material melt, vaporize, ablate or reach the ignition point quickly. At the same time, with the help of high-speed airflow coaxial with the beam, the molten material is blown away, so as to cut the stainless steel material. Laser cutting is one of the thermal cutting methods.

Water cutting: Water cutting, also known as water knife, that is, high-pressure water jet cutting technology, is a machine that uses high-pressure water flow to cut. Under the control of the computer, the stainless steel material can be carved arbitrarily, and it is less affected by the material texture. Water cutting is divided into non sand cutting and sand cutting.

Plasma cutting: Plasma cutting is a processing method that uses the heat of high-temperature plasma arc to locally melt or evaporate the metal at the notch of stainless steel material, and uses the momentum of high-speed plasma to remove the molten metal to form the notch.

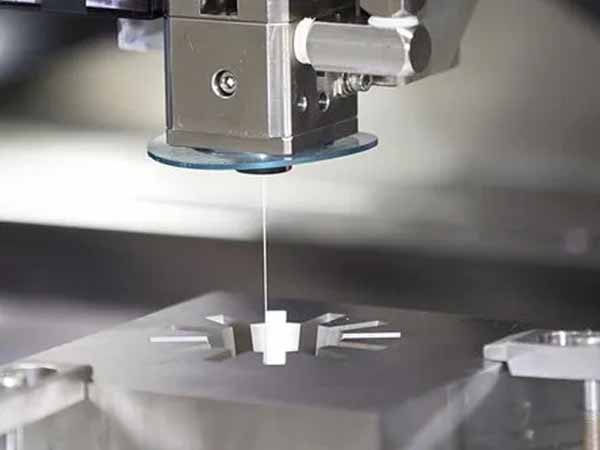

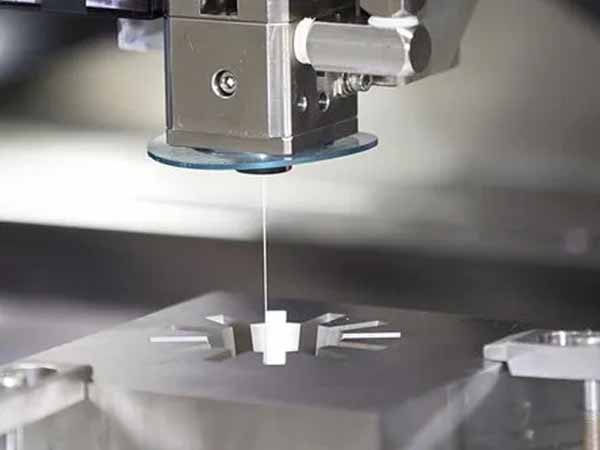

Wire cutting: Wire cutting, also known as electric spark wire cutting, it belongs to the category of electrical processing. Wire cutting can be divided into fast wire cutting, medium wire cutting and slow wire cutting. The wire speed of fast wire cutting is 6 ~ 12m / s, the electrode wire moves back and forth at high speed, and the cutting accuracy is poor. Medium wire cutting is a new technology developed in recent years, which realizes the function of frequency conversion and multiple cutting based on fast wire cutting. The wire speed of slow wire cutting is 0.2m/s, and the electrode wire makes low-speed unidirectional movement, with high cutting accuracy.

English

English Русский

Русский