Press Brake Forming: Cost Effective And Efficient?

Date:2023-05-24View:875Tags:Ronsco, Stainless Steel Sheets Bending, 304 Stainless Steel Plate

Press brake forming is one of the oldest metal forming methods in the book. Because press brake forming is simplicity, accuracy, flexibility and low cost per piece, so it has withstood the test of time and been used until now.

Press brake forming is a versatile technique, it allows fabricators that like ourselves to bend and shape metal pieces to individual specifications. Currently, as most variables are fully CNC, they are able to be programmed to exact specifications within finite margins of measurement. It means that they can rely on the easy programming abilities, creating large uniform pieces to strict deadlines and because of the measured nature, shapes are formed without causing undue stress that could lead to structural weakness later on. Besides, They are also able to store and save sets of blueprints so if a client needs exactly the same form later down the line, we can simply select their programme and produce identically formed products.

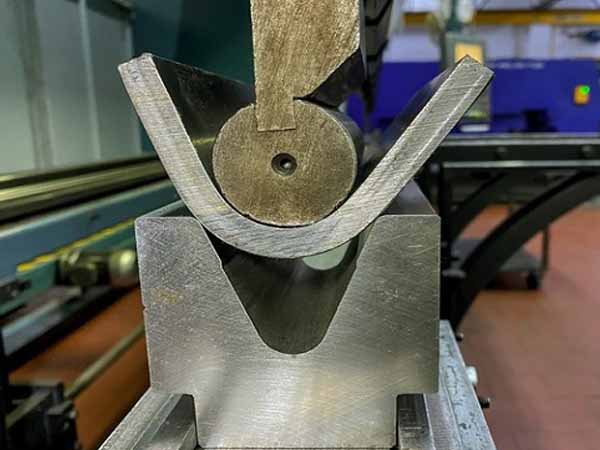

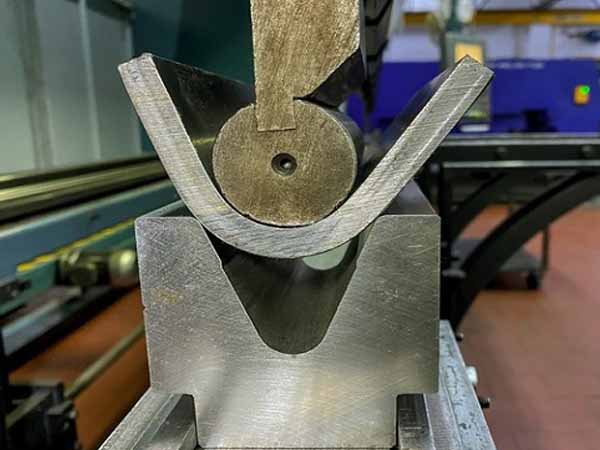

Varying shapes and sizes of die available is what makes press braking such an efficient process. They are easily switched out, so metal to be shaped to almost any angle or shape with utmost precision, but are most common in the shape of a U or a V. Theses dies allow fabricators to carefully measure and control the angle at which the metal is bent. The punch, then gradually depresses the metal sheet with a consistent level of force, creating an even and stress-free bend.

For example, metal sheets are fed automatically into the machine, before being placed between a punch and a die. The numbers of metals that can be formed in a press brake machine are vast, with the most common sheets being stainless steel. Such as Ronsco expert’s are adept at bending and shaping 304 stainless steel sheets, 316 stainless steel sheets, 321 stainless steel sheets, 310 stainless steel sheets, 309 stainless steel sheets, 2205 stainless steel sheets, 2507 stainless steel sheets etc,.

As with all stainless steel supplier, we offer free samples and quote for all our clients, to learn more about press brake forming just visit our website or send us email via service@ronsteel.com for more information.

English

English Русский

Русский